Why Regular Diesel Engine Servicing Is Essential

- Ashley Kinsela

- Sep 24, 2025

- 9 min read

Updated: Dec 19, 2025

Kind of puzzling for your friend's diesel ute, purring like a newborn kitten after 200 k's, while yours starts gagging and sputtering after a measly 100. What if I told you the trick wasn't luck, just something a whole lot simpler? Ever calculated how much you're saving by skipping that £150 service, when a new fuel-injection system could cost thousands?

Those are the things a diesel engine is great at: it keeps working forever if you treat it right. But if you neglect it, it can hit you harder than an unexpected bill from that really awful cousin who forgot to pay you last Christmas. What makes a diesel engine last up to 500,000 kilometres versus one that gives in at 150,000 falls down to one quite simple thing: diesel engine servicing. It's not about being precious with your vehicle; it's understanding modern diesels are sophisticated machines with components that need to be properly cared for.

This is that manual that hauls every necessary information concerning bringing your diesel engine to its right condition. We'll check out the most critical components that will let your engine breathe normally; why diesel fuel filtration is absolutely, thoroughly, hugely significant; and what really skipping servicing would end up costing you. It also runs through maintenance essential intervals, the best diesel filter for your vehicle, and practical tips that will save you thousands in the long run. Whether you're running a fleet of work vehicles or just want your daily driver to last, this information could mean the difference between years of reliable service and an expensive paperwork weight sitting in your driveway.

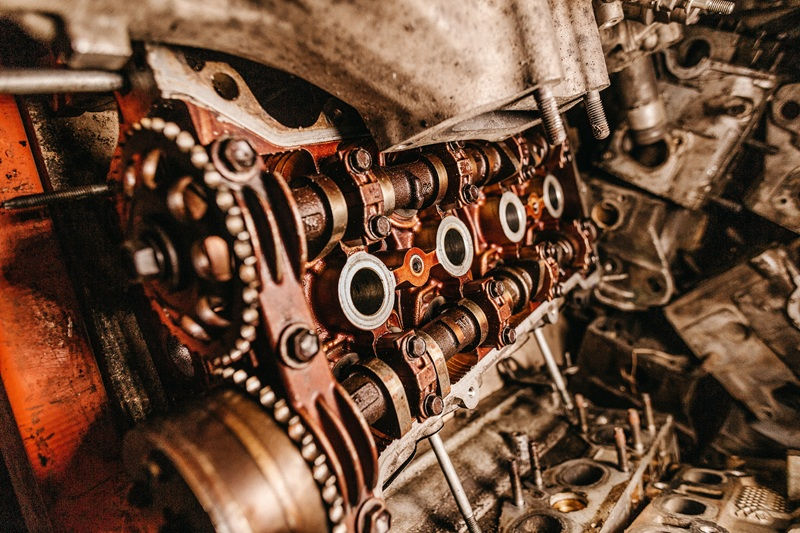

Critical Components of Your Diesel Engine

The Heart of Diesel Filtration Systems

Your diesel's filtration systems worked much like your engine's liver and kidneys; they are constantly cleaning vital components and protecting the whole system from contaminations. Add to that, the heart of the system consists of several filters working together: the primary fuel filter, the secondary ones, and the air filter, which in most cases disregarded. Yet all of these contribute much importance to keeping the engine healthy: it's the fuel filtration that could really separate an operation from getting failed catastrophically.

Modern diesel filtration has been modernized at such a rate that newer systems withstand pressures, which would have blown an older one to bits, and yet remove particulates measured in microns--that's thousandths of a millimetre. The primary filter catches the big stuff while secondary filters for common rail diesels remove particles as small as 2-5 microns. To put that in perspective, a human hair is about 70 microns thick.

Notable Features of Common Rail Diesel Fuel Filters

Arguably the main engine "defender" component is the common rail diesel fuel filter; that is, of course, unless you care more about things like emissions and pressure. Common rail diesels have tolerances extremely tight compared to what was used in mechanical injection systems: gaps smaller than bacteria. One small particle passing through can score the injector surfaces and lead to poor spray patterns, increased fuel consumption, and injector failure.

Common rail diesel filters have advanced filtration media capturing contaminants while at the same time maintaining the required fuel flow. The best designs feature graduated density layers; larger particles are caught in outer layers while finer media handle smaller contaminants. This avoids premature clogging of the filter, and thus, longer service intervals. Quality filters also have bypass valves built in to prevent engine damage should the filter become very restricted.

What Does a Diesel Particulate Filter Do?

The diesel particulate filter system is just another gizmo for emissions, but it's going to be pretty important for the engine's life on the whole. Your DPF actually catches soot particles made in combustion and holds them from entering the atmosphere. But here's a little secret that nobody really knows – a well-working DPF keeps your engine also performing just right because the proper exhaust back pressure is maintained.

The system collects soot during regular operation until a certain level is reached, and then the process of initiating a regeneration cycle starts. This burns off stored particles at greater than 600°C, rendering the soot harmless into ash. Active regenerations occur of their own accord when there is highway driving, but short trips are the problem for the car. The engine never gets hot enough to engage in regeneration, causing the filters to block and create all those dreaded DPF problems.

A mechanic curse is an engine, one of the worst things to be chained up on a Monday morning, flashing "DPF light" on the dashboard. These types of problems always start small – maybe a little less power or a little more smoke than usual. Two minutes after ignoring them, the car will be on the hard shoulder, engine in limp mode, unable to do more than 30mph as trucks thunder past. The particulate filter system can be totally unforgiving with negligence.

When it becomes impossible for an engine to regenerate the DPF, soot accumulation becomes a vicious cycle: Backpressure leads to increased exhaust gas temperatures. This, in turn, can lead to cracking of the filter substrate and melting of internal components. Once the internal structural integrity is compromised, the only way forward is to replace it entirely, which usually costs £1,500 - £3,000 depending on your car. That's just the tip of the iceberg, too; a failed DPF often takes out the turbo as it becomes oversensitive to heat and backpressure, making a further £1,000+ dent in your pockets.

Happenings with System Failure in Fuel and Their Crippling Repair Costs

Let's just talk numbers that can make the very depths of your wallet cry. For example, a single failed common rail injector alone goes for between £300-£600 and that's just for the part. Labor adds another £150-£300. But the catch here is when one injector becomes clogged due to contamination, the others usually follow suit within a few months. You now need to buy a new set worth £2,000-£3,000. And what about the high-pressure fuel pumps? Without an extra £1,500 swelling the cost, these are set to be installed up to £2,500.

Massive is the terrible cascade effect of fuel system failure. Micron-sized metal debris from a pump that is about to fail flies through the entire system, settling in every component. Fuel rails, pressure sensors, and return lines essentially either have to be replaced or thoroughly cleaned. Some workshops quote £5,000-£7,000 for complete common rail system overhaul – enough to write off older vehicles entirely. Such failures are usually not covered by insurance, as they are classified as service-related failures rather than accidental damage.

Performance Loss: When Your Ute Starts Feeling Sluggish

The gradual decline of power in those last times is not merely due to age; after all, diesel slowly dies, and performance is suffocated. The injectors are dirty, and hence they spray poorly, which means that the fuel burns incompletely. This you will begin noticing when overtaking or climbing hills. What was easily accomplished now becomes difficult, at times requiring dropping gears and carefully timed overtaking manoeuvres. Increased consumption of fuel becomes noticeable, up to 20-30%, which costs hundreds more a year.

And clog diesel filters which deprive the engine of fuel under heavy demand; your management system then limits power output against damage. When modern diesels suffer reduced drive, their defines mechanisms kick in: maximum boost pressure and injection timing are limited, so the 'limp mode' gets you home, but who needs an 180kW Ute performing like a 90s hatchback?

Essential Servicing Components: Just What Must Be Attended?

Diesel Fuel Filter Replacement Interval

Most manufacturers stipulate between 10,000 and 30,000 kilometres for the replacement of diesel fuel filters, but those distances actually assume ideal conditions, which seldom apply in reality. Dusty roads, poor fuel quality, and extreme temperatures are the standard in Australia-hence, the most frequent changes. Most diesel authorities will make the general recommendation that all of these manufacturers' intervals should be halved for those vehicles that do a lot of heavy towing, off-road work, or mostly short runs when engines do not reach full operating temperature.

The apparent savings of extending filter changes soon turn out to be false economy when actual costs are measured. Sure, stretching a £50 filter for 40,000-kilometres might save you £50 a year-you'd almost be saving up for another filter. Contamination causes failure of but one injector, however, and ten years of "savings" are wiped out. Premium filters may cost a little more, but usually, they reduce running costs by providing greater and more genuine filtration life. The ideal diesel fuel filter must balance cost with protection reasonably, the best models usually costing in the £30-£70 for quality units range.

Maintenance of Fuel Filter with Water Separator

Your fuel filter and water separator truly needs service much more often than the filter itself. Collect the water surprise that can happen in humid coastal areas or with very temperature-variable situations. Checking and draining the separator should happen monthly, or even weekly during wet seasons. Literally takes two minutes and could save you thousands of damage.

Draining procedure differs by design, but most open a valve at or near the bottom of the separator until clean fuel comes out. Some have transparent bowls that give a visual of the water levels-if you see the distinct layer, immediate draining is necessary. Electronic water-in-fuel sensors inform you of dangerous levels, but don't rely solely on these. Sensors can fail, and your warnings might come too late. Damage could already be occurring upstream.

Particulate Filter Systems Cleaning and Regeneration

Most important, professional DPF cleaning has come to be recognized in normal maintenance of modern diesel vehicles, primarily for those driving within cities, through the urban traffic gridlock. Generally, simple regeneration burns off soot; professional cleaning, however, will remove the ash accumulated, since it cannot be eliminated during regeneration. This ash, which primarily comes from additives in the engine oil, gradually decreases filter capacity until regeneration is no longer possible.

Cleaning consists of removing the DPF and cleaning the filter using specialized equipment and tubes to flush out contaminations within. Some operate on pneumatic pulsing to dislodge ash, while others employ thermal cleaning that bakes filters at controlled temperatures. Quality services also test flow rates before and after cleaning, ensuring restoration to near-new performance. Costing generally between £300-£500, it's a worthwhile investment when replacement costs are over £2,000.

Best Diesel Filter for Your Vehicle

Diesel Fuel Filter Comparison: OEM vs Aftermarket

The constant, endless debate between OEM versus aftermarket filters essentially becomes a battle between money and confidence. OEM filters are assured by the fact that they are built precisely to specifications and fit the way they should, tailored to the requirements of your engine. Their application includes the testing of production development, with an innocent mind concerning protection and performance. But OEM filters come at a price, about 30-50% more than a quality aftermarket alternative, and just that leads many to wonder whether the extra cost is worth it.

With careful selection, quality aftermarket filters can sometimes equal or better OEM performance. Baldwin will supply Fleet guard and Donaldson filters to manufacturers of construction plants globally using similar technologies for their aftermarket ranges. The key is not just the fluid mechanics of fit but also whether they meet or exceed OEM specifications. A proper diesel fuel filter comparison takes into account the efficiency of filtration, capacity, rate of flow, and quality of construction.

Best Fuel Filter for Diesel Engines in Australian Conditions

Filters in Australia are designed for extremes. Dust levels in countries are more than what European manufacturers would ever consider during their designing phases. Temperature swings occur between frosts in the night and 45 degrees during the day, putting further strain on the materials of the filter. Another aspect is biodiesel blends, which introduce variable fuel quality. Diesel filters that are considered the best for these conditions are at high tension and denser in contamination capacity.

Multi-stage filtration works quite easily in the Australian environment. These primary filters are rated at 30 microns, which will catch larger contaminants and water, but they will protect the 5-micron secondary filters from clogging too early. This guarantees that it will extend service intervals and still keep protection. Some premium filters integrate in a bypass fashion a mechanism that continuously cleans part of the fuel to sub-microns, giving the final straw at very high contamination events.

Filter Quality Understood: Diesel Filters Differ by Quality

Almost imperceptibly, superior construction marks premium diesel filters against their inferior budget versions. Premium filters employ synthetic media that retains consistent pore sizes throughout the structure. Cheaper filters often have cellulose-based media, which degrades in the presence of water and fuel additives. On microscopic examination, a good media shows an even fibre distribution, while older products have gaps and inconsistencies so that impurities can pass.

Different pleat spacing and support greatly affect the performance of the filter. The quality filters keep their pleat spacing even under flow conditions-always full use of the surface area. Poor designs allowed the pleats to bunch together, actually reducing the effective area and leading to increased pressure drop. Metal end caps and center tubes of premium filters resist deformation under pressure, while plastic parts in budget filters would collapse to cause a catastrophic failure.

Conclusion:

Waded through everything from how common rail diesel fuel filter systems work to quite simply the death knell of repair costs when things go wrong. A message consistent throughout all sections-no, regular service to a diesel engine is not an expense-it is the investment into your diesel's future longevity. That high-pressure fuel system, with the batch of filters and water separators, was intended to work as a singular component towards a complication-free running engine, only under strict maintenance.

Comments